24/7 Emergency

Repair & Retrofit Services

Troubleshooting

Our Technicians excels in quickly identifying the root cause of issues, troubleshooting on-site to determine the most effective parts and solutions for your machinery.

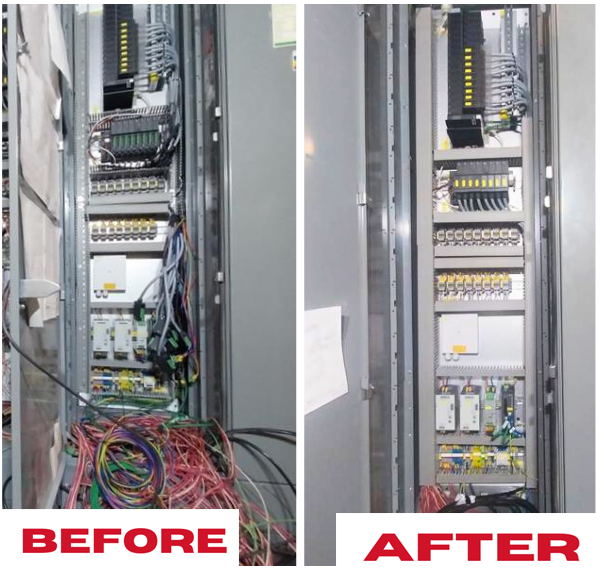

Custom Retrofitting

Upgrade your existing machinery to meet current standards and improve efficiency with our tailored retrofitting solutions.

Rapid Machine Repair

From simple fixes to complex malfunctions, our technicians swiftly diagnose and repair your machinery.

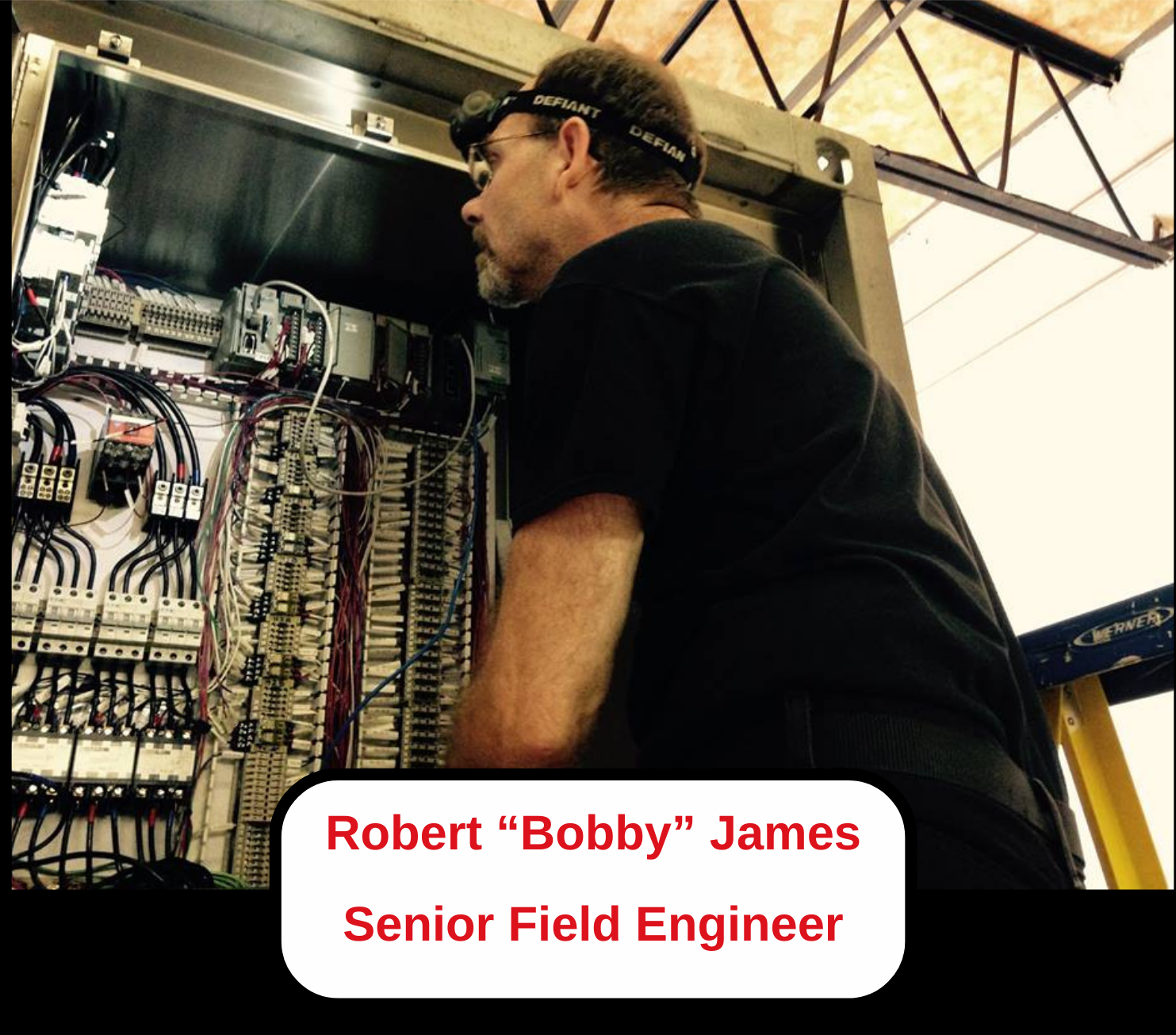

Field Service

Our fleet of field service technicians is always ready to provide on-site assistance.

24/7 Emergency

Repair & Retrofit Services

On Site Service

When your machinery faces unexpected downtime, the cost and stress can quickly escalate. That’s where our team of expert field service technicians comes in. Equipped with extensive experience and a toolkit for any situation, we bring the solution directly to your doorstep, ensuring your operations are back up and running with minimal delay.