There could be a multitude of reasons why someone would need a custom control panel. A control panel will manage communication between an assembly of a systematic and standard arrangement or two or more components, so it is vital that the control panel is built in a way that allows for the performance of specific tasks. A custom control panel is a purpose-built solution that is individually engineered for the client at hand.

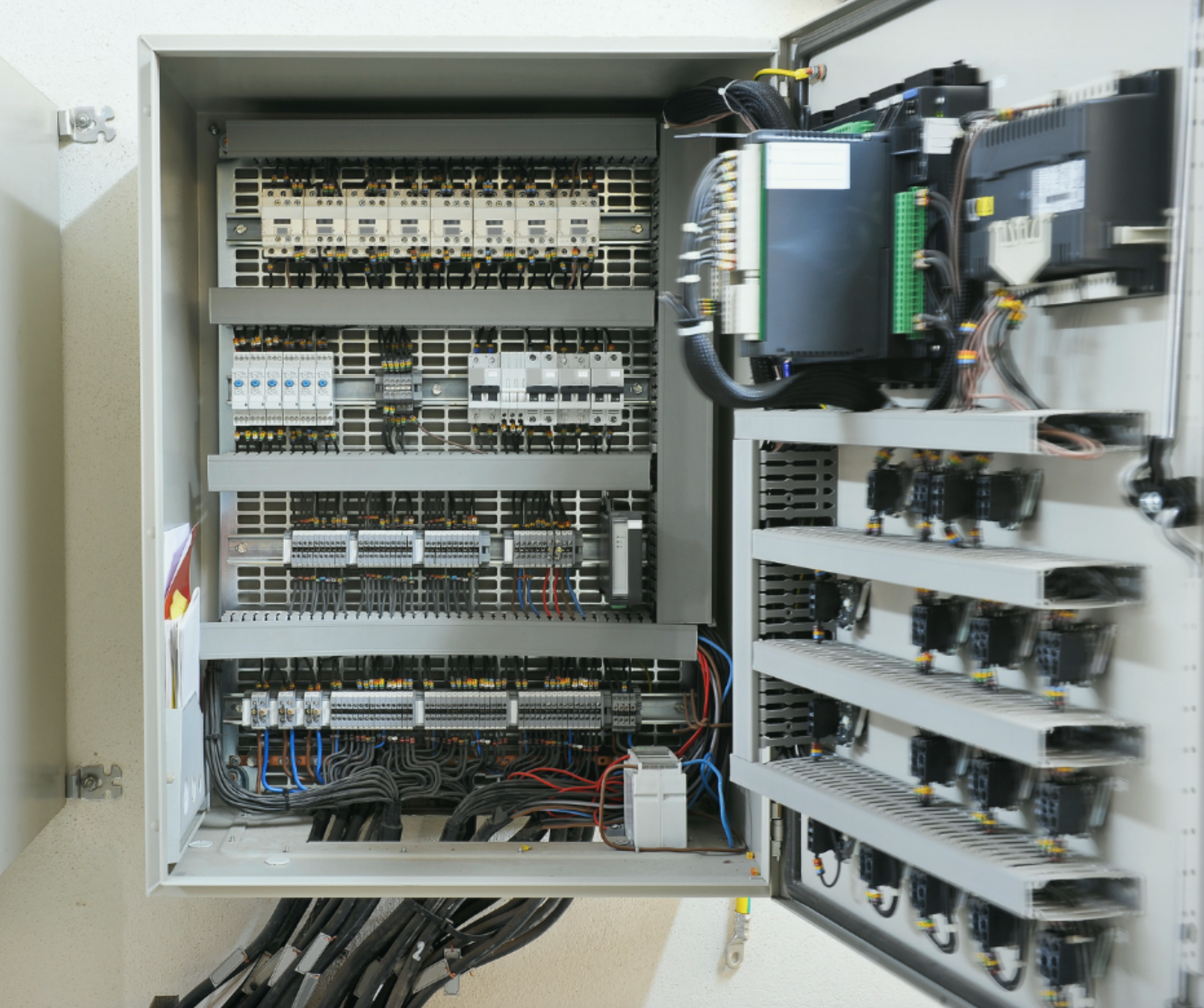

There are many components that go into control panels to ensure safety and reliability. Custom controls contain motor controllers, such as circuit breakers, overload relays, transformers, and fused disconnect switches. Other things custom control panels can contain are selector switches, timers, switches, pushbutton stations, terminal blocks, and any other things that are necessary for controlling machinery and equipment.

Circuit Breakers –

Circuit breakers will detect when there is excess electrical current by opening or breaking the circuit to stop the flow of current. This will protect an electrical circuit from becoming damaged.

Overload Relays –

To turn a device on or off, relays are used with an electronically or magnetically operated switch. Relays will typically allow low currents to activate higher currents. By directing the lower current to flow through an input circuit to activate an electromagnet, the relay can complete this activation.

</p

Transformers –

Transformers will manage the AC voltages between circuits, reducing or increasing as necessary. An industrial control panel transformer will typically be used to convert incoming 480V AC to 120V AC, therefore other devices in the control panel can utilize it.

Fused Disconnect Switches –

The purpose of a disconnect switch is to completely disconnect the control panel from its electrical supply. The typical use for a disconnect switch is to shut off power to the control panel while maintenance or repairs are happening, as well as for emergency stoppages.

Selector Switches –

Selector switches are on the front of a panel and are easy to locate and touch. Typically listed as a terminal block, selector switches come as a complete unit which makes it ready and easy to install.

Ethernet Switches –

To keep communication between devices inside the control panel, an ethernet switch is used. It can connect PLCs, VFDs, and HMIs, as well as networked devices outside of the panel like SCADA systems, information systems, and other control panels.

Pushbutton Stations –

A pushbutton station is used to turn the control circuit on and off. In electrical automatic control circuits, it will be used to manually send control signals to control contactors, relays, electromagnetic starters, etc.

Terminal Blocks –

Terminal blocks are connection points. They can join two or more wires together, and can even be arranged together in a strip to direct power from one source to various devices in the control panel.

What Industries Use Custom Control Panels?

Although there is a lot that will go into custom control panels, ultimately components will be different from client to client, while some components are standard for every control panel. Certain industries are more likely to require a custom control panel, such as the following industries:

- Manufacturing

- Chemical manufacturing

- Oil refineries

- Water & wastewater treatment

- Electric power generation

- Telecommunications

Infinity Industrial Controls is a certified control panel manufacturer building to UL508a standards. We specialize in the design, fabrication installation, integration, troubleshooting, emergency servicing, and maintenance of turnkey automation systems. For any questions on custom control panels, please call!

[popup_anything id=”9350″]